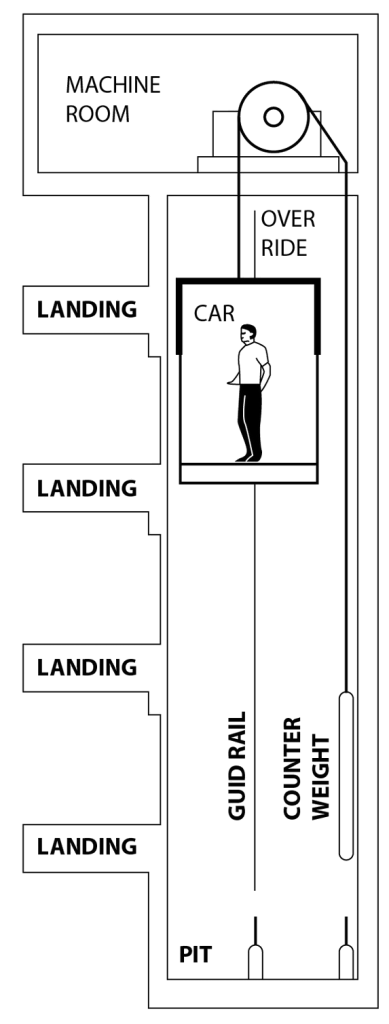

Compared to other kinds of elevators, traction systems are the most common in the market for enhancing mobility in high rise buildings. In this kind of configuration, the elevator cab is pulled by straps of ropes, rolling over a sheave or pulley. However, some modern traction systems use flat steel belts. Depending on your mobility needs, structure of the building among other factors, you can opt to install one or two traction elevators.

The traction system is designed in a way that the weight of the car that holds passengers and cargo is balanced through counterweight. But, in cases with so much traffic, it would be advisable to install two lifts that travel in opposite directions. Considering the simple technical and mechanical configurations of traction systems, they are quite energy efficient in high rise property.

Types of Traction Elevators

There are different kinds of traction elevators available in the market including, geared and gear-less traction elevators, machine room-less traction elevators among others.

Geared Traction Lifts

Just as the name suggests, geared traction elevators are controlled by gears and other features, which are piloted by electric motors. The motors can either be AC or DC. Although the lifts move at a relatively slower rate than gear-less elevators, the fact that they operate on electric motors still gives them an edge and better capacity to facilitate efficient travel across different floors.

Traction machines are typically designed to travel at speeds ranging from about 38 to 152 meters per minute. And, can accommodate a capacity up to 13,600kg. The elevator is equipped with an electrical braking system that is placed between the reduction unit and motor. As the elevator approaches the designated floor or level, the brake is automatically applied to keep the car in position before proceeding to the next.

Due to the high supply of more affordable compact AC drives in the market today, there is an increased integration of AC motors with variable speeds into most installations. As a result of this, there is enhanced efficiency without a lot of complications. In fact, many manufacturers are gradually shifting from MG-based systems in an attempt to improve convenience while also conserving energy.

Geared traction elevators are ideal for low to mid-rise establishments standing at about 76 meters tall. Compared to a gear-less traction elevator, geared systems are usually less expensive to install. Besides, they also have faster speed that several other kinds of lift hoist systems. With a geared traction lift, you can also choose to install the machine room either at the basement or on top. This type of elevator can also work quite well for new establishments and modernization.

Gear-less Traction Lifts

The gear-less traction elevator was first developed by Otis and has been a common facility in most landmark buildings. Although it is mainly suitable for mid to high rise property of up to 610 meters, a gear-less system can also be installed in mid or tall buildings. In fact, the product has proven quite efficient and durable in a wide range of buildings. A properly maintained gear-less machine is very fast hitting speeds of more than 152 meter per minute.

A gear-less traction elevator is piloted by hoisting pipes and drive sheave working in coordination to move the car. One end of the hoisting pipes or cables are attached above the lift while another is connected to a counterweight so as to facilitate ascent and descent. The weight of the car together with that of counterweight aligns the hoisting pipes to grooves, providing the required traction for the movement of the elevator from one floor to another.

Depending on the design of the elevator, architects need to calculate the counterweight to complement the load of the lift car. Besides, the counterweight should also be half that of the recommended passengers in order to create a proper balance for the smooth operation of the elevator. As the elevator car moves upwards, the counterweight moves in the opposite direction to strike a balance.

Similar to geared traction elevators, gear-less traction machines can also have their machine room installed at the basement or overhead. However, they are highly efficient than those with gears when it comes to energy consumption. Besides, gear-less traction elevators also have smooth ride quality and can as well accommodate both rear and front openings.

Machine Room-Less (MRL) Traction Elevators

These elevators have revolutionized the industry mainly because of their ability to operate without machine rooms. Highly recommended for mid to high-rise establishments, MRL traction elevators can travel up to a distance of 76 meter. Instead of a fixed machine room, these elevators are installed either overhead or on the side of the hoist way. Besides, it also has a motor that is permanently fixed using a magnet.

The fact that machine room-less traction elevators do not require a machine room makes them ideal in saving space. However, they have main controllers, which are installed either on the upper or basement floors. There are also some models whose controller cabinets are situated within the frame of the door. MRL traction elevators can serve buildings with up to 20 floors but, it should be noted that the system is gear-less.

Benefits of Traction Elevators

Despite a few similarities in lift hoist systems, traction elevators are quite unique in design, construction and installation. One of the key features of traction elevators, which gives than an added advantage over other systems is, they have to limitation on machine room design. This option helps in space conservation and could also prove cost-effective. Besides, their smaller electric motors also consume less energy, making them quite efficient.