The hydraulic system is a type of lift hoist mechanism that is applied in the design, construction and installation of elevators. The concept of hydraulic elevators is quite simple, mainly consisting of a compartment (car) attached to a lifting system. The system mainly works by lifting the car through a hydraulic ram, which is a fluid-driven piston situated inside a cylinder. The cylinder is linked to a system that pumps fluid to facilitate upward and downward movements of the elevator.

The Main Components of Hydraulic System

Although there are several features shared by lift hoist mechanisms, there are certain varying components. And, it is only by knowing these unique components that you will be able to properly distinguish a hydraulic system from other types of elevators. The two unique components of a hydraulic elevator are the machine or drive system and safety system.

Machine/ Drive System

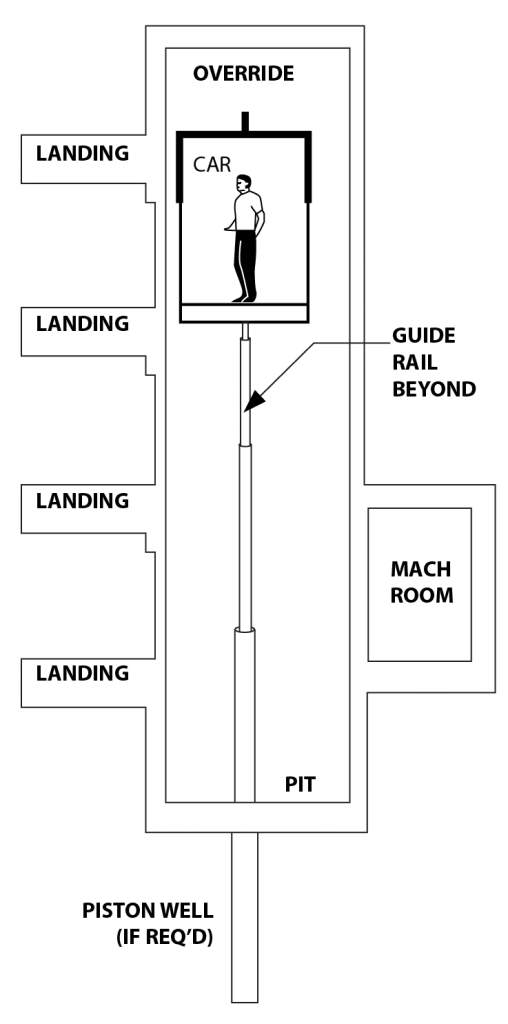

The elevator car is piloted by either direct action or indirect action. In a direct action setting, the hydraulic ram is located at the side or back. Direct acting below the car is usually not recommended unless with specification from a lift expert. The machine system includes, a piston/ plunger/ jack that houses the cylinder and ram. Another component of the drive system is the hydraulic power unit that consists of tank, valve, actuator and motor or pump. For roped hydraulic elevators, the machine compartment also comprises a suspended system

Safety System

The safety of the individual using the elevator is always given precedence in every design and model. Some of the key components of the safety system include a manual reset slack rope safety switch, final limit switch, seismic valve for hydraulic lifts, buffers, manual emergency operation. Other safety devices also included in a hydraulic system are pump run timer, pit switch, emergency battery back-up among others.

How a Hydraulic System Works

A hydraulic system comprises a fluid reservoir or tank, pump, electric motors and valve, which is installed between the reservoir and the cylinder. In most cases, oil is used as the fluid but other in-compressible fluids can also be effective. Each of these components performs a dedicated task to collectively facilitate the smooth movement of the lift upwards or downwards as well as stops at various levels of the building. Other than enhancing the efficiency of the machine, the features also ensure comfort and safety of users.

The operation of a hydraulic system mainly depends on the pumping of the fluid from the tank into the cylinder. Whenever the valve is closed, the pressurized fluid has nowhere else to escape except into the tank, lifting the piston up. As a result of this, the elevator car is able to move to designated floors on the upper level of the building.

As the elevator nears the floor where it is scheduled to stop, the control system sends a signal to the electric motor to gradually switch off the pump. This will stop the flow of the fluid into the cylinder. However, the fluid that is already pumped into the cylinder remains trapped because the valve is closed. As the car reaches the desired level, the piston goes into rest on the fluid so as to hold the elevator in place before moving to another floor.

Whenever you want the lift to take you down, the electric motor will signal the valve through a solenoid switch. As the valve opens up, the fluid in the cylinder is pushed back into the reservoir. The weight of the car and its cargo or passengers pull down on the piston, thereby forcing the fluid to flow into the reservoir and making the lift to move downwards. As the car approaches the required level of the building, the control system caps the valve, causing the car to come to a halt.

Types of Hydraulic Elevators

When shopping for a hydraulic lift, it is also important to note that they are classified into two main categories; holed and hole less hydraulic elevators.

Holed hydraulic elevators

Also known as conventional hydraulic elevators, this type of hydraulic system is equipped with a sheave that runs through the bottom of the elevator pit. The machine uses an underground hydraulic cylinder to facilitate upward and downward mobility of the car.

Hole-less hydraulic elevators

Developed in the 1970s, hole-less hydraulic elevators work through a pair of above ground cylinders. The elevator is fitted with one piston, which can be placed on either sides of the lift car. Hole-less hydraulic elevators can be further broken down into three main categories;

- Telescopic hydraulic elevators – This is a configuration whereby telescoping pistons are installed at the bottom of the pit. However, it does not require a sheave or hole under the pit. This type of hydraulic elevator has two or three pieces of telescoping pistons that can allow a travel distance of up to 150 meters.

- Non-Telescopic Hydraulic Elevators – This configuration involves just one piston and can facilitate movements over a distance of up to 6 meters.

- Roped Hydraulic Elevators – Roped hydraulic elevators use a mix of ropes and a piston to facilitate the movement of the lift. The configuration allows a travel distance of about 18 meters.

Advantages of Hydraulic System

Hydraulic elevators have become a force to reckon with in the market mainly because of the cheaper costs incurred in their installation and repair. Compared to electric elevators, hydraulic systems have a more vibrant safety record, which also makes them a great choice for many homeowners. The elevators have been proven to be quite safe in areas that are prone to earthquakes.

Since hydraulic elevators are installed onto the foundations of buildings, they are also less vulnerable to the risks of shaky establishments. Considering the fact that the lifts are not electric, it can also be said that hydraulic systems are energy efficient and eco-friendly too. Besides, they also require low maintenance, making them more cost-effective to use in your establishment.

Hydraulic elevators also offer greater flexibility in design and construction, which means our architects at Home Lift Singapore can always design a customized one to perfectly suit your budget, property and accessibility needs.